The best resolution for an industrial display depends on the application and viewing conditions. Here’s how to decide:

When Higher Resolution is Better

Detailed Visualization Required

- Used in medical imaging, precision engineering, or CAD applications.

- Example: Semiconductor manufacturing or quality inspection screens.

Large Screens with Close Viewing Distance

- If operators view the display up close, higher resolution improves readability.

- Example: Control rooms or complex monitoring dashboards.

High-End Image Processing or AI Applications

- Required for machine vision, automation, and AI-driven defect detection.

- Example: Smart factories using high-res cameras for real-time analysis.

When Lower Resolution is Enough (or Better!)

Far Viewing Distance

- If users see the screen from several meters away, extra resolution is wasted.

- Example: Factory status boards or warehouse inventory displays.

Power & Performance Efficiency

- Higher resolution requires more processing power and energy.

- Example: Outdoor signage and battery-operated devices.

Legacy System Compatibility

- Older systems may not support ultra-high resolutions.

- Example: Older industrial equipment interfaces.

Balanced Approach

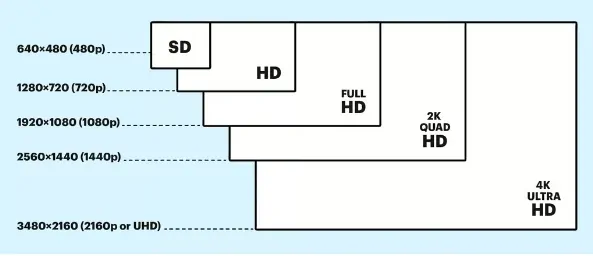

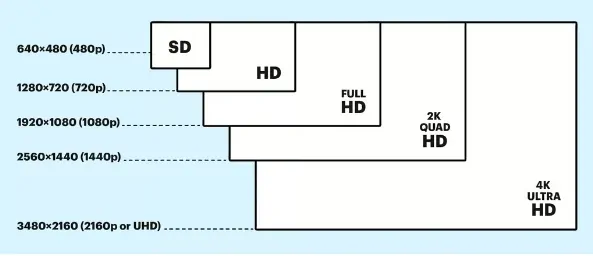

- 1080p (Full HD)– Standard for most industrial applications.

- 4K (Ultra HD)– Ideal for high-detail tasks but requires powerful GPUs.

- 720p or lower– Suitable for text-based interfaces or distant viewing.

LCD Displays & OLED Display product links for reference:

https://www.youritech.com/products/ips-displays/